Make Your Move to

Thermal Conversion

Eliminate the challenges of municipal

solid waste management with Landaira

The patented Thermal Conversion system (US Patent No. 11,098,251 B2 and US Patent No. 11,584,893 B2) uses low volumes of oxygen and a thermal decomposition process to change the molecular structure and chemical composition of MSW in a closed-environment batch system. Waste is reduced to carbon, ash residue, and usable synthetic gas at the molecular level with:

No Sorting

No Drying

No Shredding

HOW IT WORKS

The molecular structure of hydrocarbons in carbon-based waste is continuously broken down by combining low temperature heating in pressurized containers with controlled, low-volume air circulation to create a completely controlled decomposition process. It’s the only way to enable true thermal chemical conversion.

1 Waste destined for the landfill is collected and packaged into manageable bales — without sorting, drying, or shredding. Bailing removes the issues of smell and leeching.

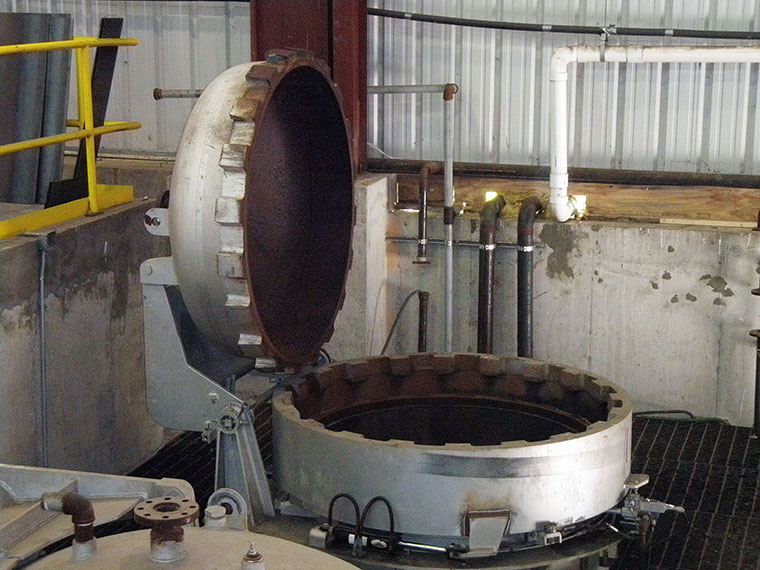

2The bales are placed in the patented thermal conversion processing containers, which are then lowered into an autoclave.

3The patented thermal conversion is initiated to bring the waste in the autoclave up to 600° C to 800° C at a low pressure of up to 150 PSI to start the decomposition process.

4A very low volume of air is circulated in the autoclave chamber to enable the patented thermal conversion until the waste is reduced to carbon and ash residue, and any remaining recyclables.

MAINTAIN CONTROL

The low-heat patented Thermal Conversion process uses batch processing, downdraft thermal conversion, pressure, and Autoclave Processing Modules (APMs) to create unprecedented control. Our customized system monitors thermal conversion levels, with automated controls adjusted to achieve complete decomposition. Once the process is completed, the container is removed from the autoclave, a new container is loaded, and the process repeats.

Convert Waste Into Carbon, Synthetic Gas, and Energy

The patented Thermal Conversion can be configured to produce carbon, synthetic gas, electricity, and sterilized recyclables.

Ash Residue

The patented Thermal Conversion process eliminates up to 95% of all solid waste fed into the system. The remaining material is carbon and ash residue that can be used as a leech aid for existing landfills.

Synthetic Gas

The patented Thermal Conversion process can be used as a fuel for boilers and steam generators, which can be combined with an Organic Rankine Cycle generator, steam turbines, or other generators that can operate on low BTU gas to generate electricity.

Sterilized Recyclables

Household metals and glass in MSW are completely sterilized through the patented Thermal Conversion process. Pre-sorting, drying, and shredding are not required.

Harness the Power of the Thermal Conversion system

The patented Thermal Conversion system has been recognized by the United States Environmental Protection Agency (EPA) as a unique process that does not require combustion of solid waste for thermal conversion.